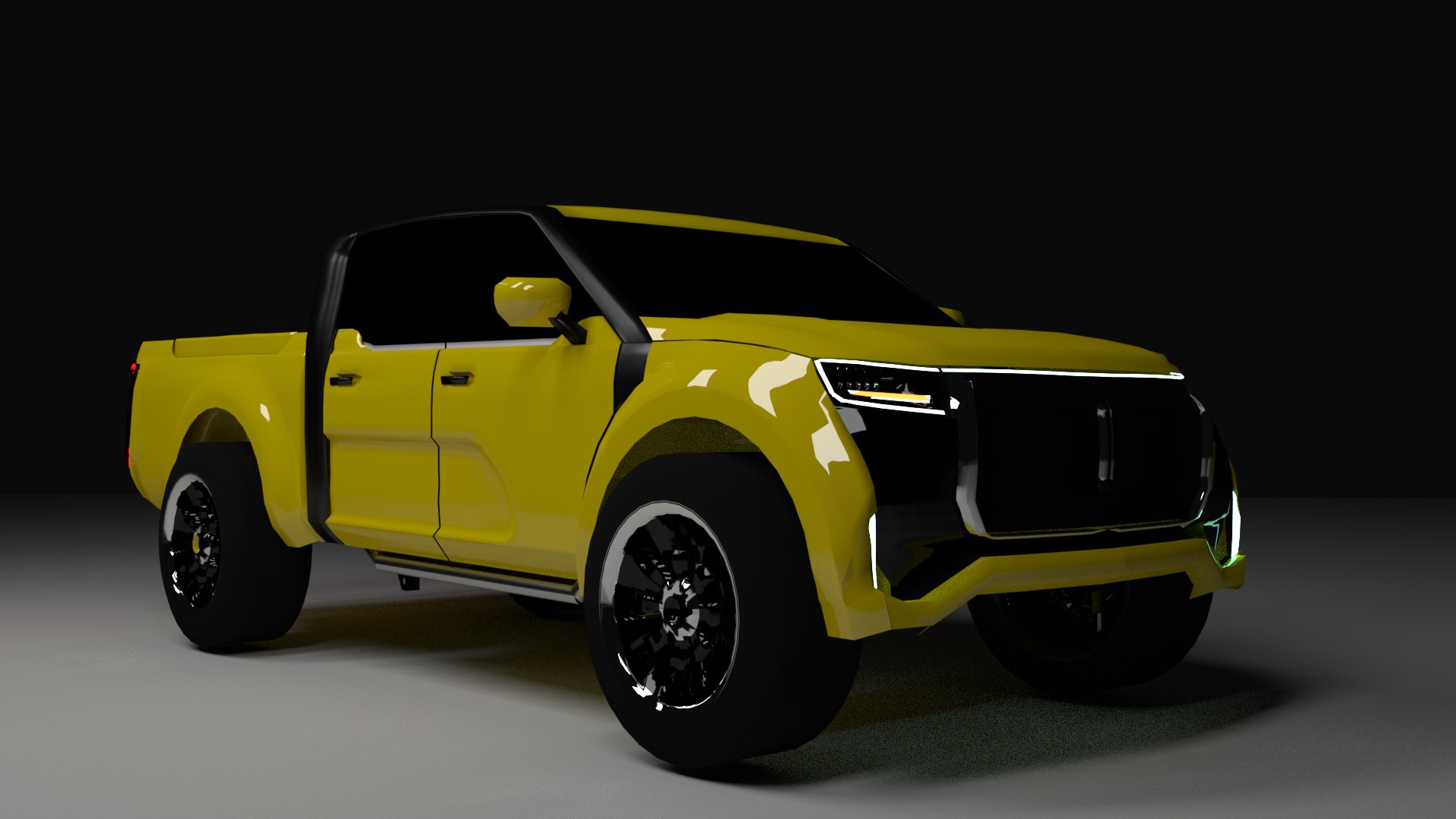

An African vehicle brand registered in Zimbabwe and South Africa, Mureza Auto Company is set to commence assembling cars in Zimbabwe by next year after initial footprints on the South African soil.

The company is headed by a Zimbabwean chief executive officer Tatenda Mungofa and the name Mureza is a Shona name for a flag.

Mr Mungofa earlier revealed to this publication that the company intends to be “the flag waver for the indigenous African motor industry” as well as complement or surpass companies like Henry Ford who replaced horses with affordable cars.

Mureza’s September media release notified of the company’s purported joint venture with a Tehran (Iran) based French registered Société Anonyme Iranienne de Production Automobile (SAIPA Group), for the supply of components with an ultimate goal to manufacture vehicles in Africa for African drivers.

The company expects to provide new but cheaper alternatives to tame the proliferation of used imports which are heavily taxed in isolated African markets. Zimbabwean operations which will commence in 2020 will be through the group’s partnership with a local car assembling company, Willowvale Motor Industries. The group, however, eyes more partnerships with other local component suppliers whose products shall be subjected to some quality checks.

“Operations in Zimbabwe are set to start in 2020. As a brand and as a company, Mureza’s vision is one of epic proportions and as common practice in business, that’s something we cannot work towards in solitude so we have recognised a number of local partners with Willowvale Motor Industries being one of our key stakeholders.

“Besides our partnership with Willowvale Motor Industries, we are looking at possible component suppliers from within Zimbabwe.

“Tyres, batteries and other accessories that need to be changed frequently are some of the things we are hoping to source locally. However, we have a strict quality control system that we run in that regard to ensure that the quality of the vehicles is not compromised.”

Mureza, however, declined to reveal the initial amount to be pumped into Zimbabwean operations but instead promised smooth operations with prior mobilisation of all required resources. Initial projections are of 35 units per month.

Said Ms Chido Nemhara, Mureza’s public relations officer: “Car manufacturing is expensive and made up of complicated processes. As a company we have resources in place for the smooth running of production once we start operations in Zimbabwe come 2020. Production is starting with 35 units per month,” she said.

Ms Nemhara said success prospects of the Zimbabwean investment are great considering the concern by locals in the business as well as the general acceptance of the brand by Zimbabwean citizens;

“The existence of the Mureza brand has been established and the people of Zimbabwe are talking about it and will still be talking about it for a very long time to come. Furthermore, the brand has gotten attention from the right people in the business to ensure that it keeps growing. This gives us the confidence to say that although we still have a lot of work to do, our brand has started on the right foot,” she said.

The vehicle manufacturing company promised diverse payment methods other than mere cash in recognition of a differentiated local and international market.

“Our aim as Mureza is to provide transportation solutions to Africa as a whole and selling the vehicles at cash basis only contradicts our cause so there will be a number of payment terms and options for our consumers,” said Ms Nemhara.

Meanwhile, the Minister of Finance and Economic Development, Professor Mthuli Ncube, promised great support for the motor industry in his 2020 National Budget announcement. He proposed the suspension of duty on semi-knocked down (SKD) kits used by the motor vehicle industry, which facility he proposed to be extended for a further three years from now. Growth of the motor industry is further supported by the Government after it launched the Zimbabwe Motor Industry Development Policy (ZMIDP) in June 2018 with a view to raise production capacity from 10 percent per year to some commendable capacity by 2030.